Neopor® BMB: Reduced CO2 footprint with the high performance you trust

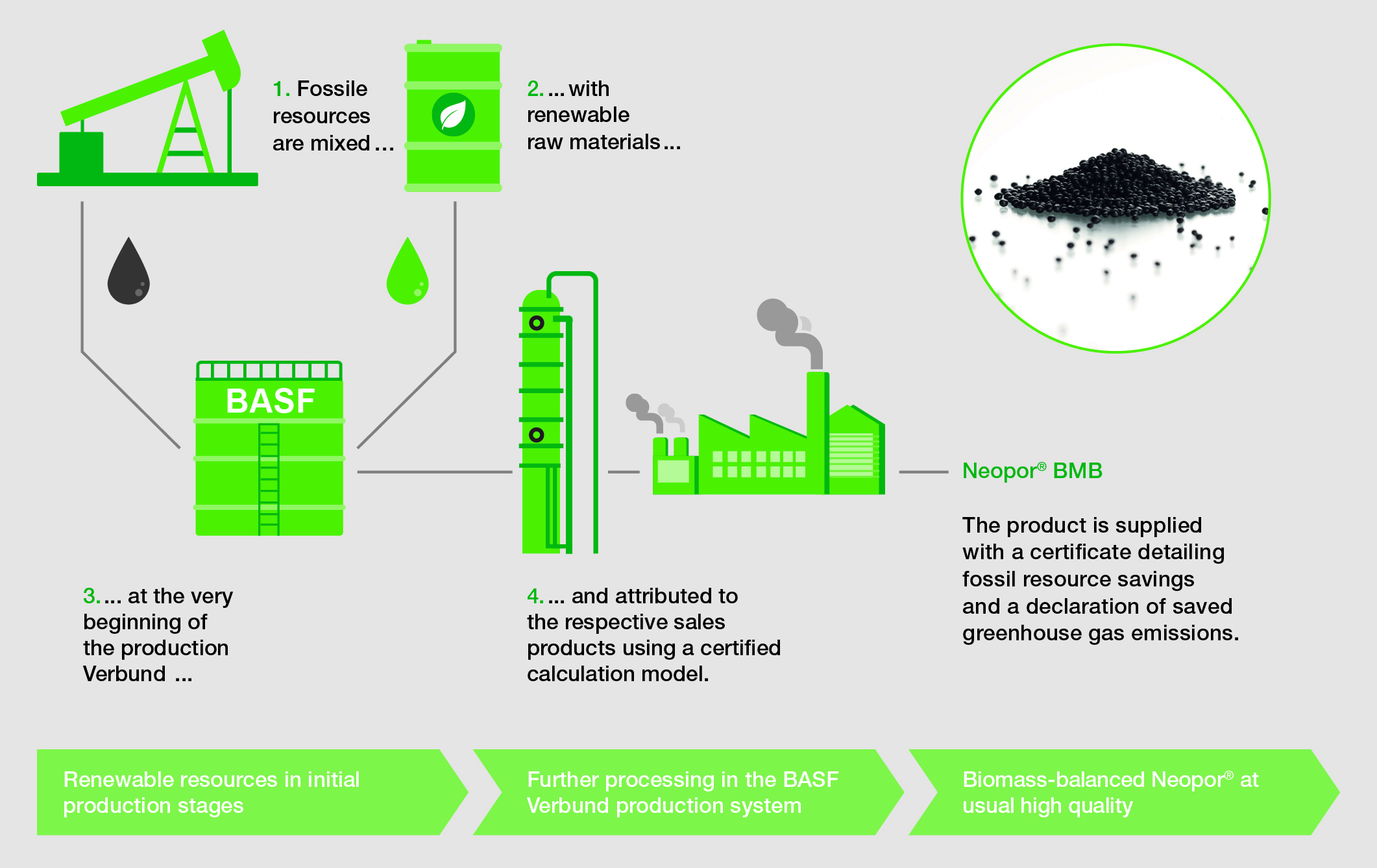

With the biomass balance (BMB) approach of BASF , fossil resources needed to produce Neopor® can be replaced 100% by renewable raw materials. This production method saves valuable resources while reducing the CO2 impact. The carbon footprint of Neopor® BMB improves by 90 percent compared to conventionally produced Neopor®. At the same time, all important product properties are retained.

Insulation materials made of Neopor® - even in its conventional form - already make a large contribution to sustainable building thanks to their long lifespan on a thermally insulated facade.

Read more about BASF's biomass balance approach with Neopor®

TOP